| Alloy Names (as per RoHS specifications) | |

|---|---|

| IS/ISO | CuSn6 |

| DIN CEN/TS 13388 | CW452K |

| UNS | C51900 |

| JIS | C5191 |

| Chemical Composition | Weight percentage |

|---|---|

| Tin [Sn] | 5.5 % to 7.0 % |

| Phosphorus [P] | 0.02 % to 0.10% |

| Zinc [Zn] | 0.30% Maximum |

| Lead [Pb] | 0.05 % Maximum |

| Copper [Cu] | Remainder % |

| Characterists |

|---|

|

| Main Applications |

|---|

|

Electrical : Contact Springs,Electrical Flexing,Contact Bladers,Terminals,Switch Parts,Electrical Flexing. |

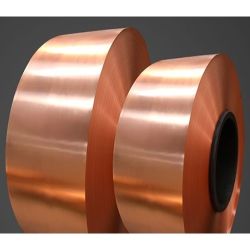

Phosphorus Bronze Strips

Properties

| Density | 8.8 | g/cm3 |

| Thermal expansion coefficient - 191..16 | 18 | 10-6/K |

| 0..300°C | 18.5 | 10-6/K |

| Specific heat capacity | 0.377 | J/(g·K) |

| Thermal Conductivity | 75 | W/(m·K) |

| Electrical Conductivity (1 MS/m = 1 m/(O mm²) | ≥ 8 | MS/m |

| Electrical Conductivity (IACS) | ≥ 13 | % |

| Thermal coefficient of electrical resistance (0 .. 200 C) | 0.65 | 10-3/K |

| Modulus of elasticity (1 Gpa = 1 kN/mm²) cold formed | 102 | Gpa |

| 118 | Gpa |

| Temper | Tensile Strength | Yield Strength |

| Rm | Rp0.2 | |

| MPa(N/mm2) | MPa(N/mm2) | |

| O (Soft) | 340 Min | ≤ 300 |

| HA (Quater Hard) | 385 Min | ≥ 350 |

| HB (Half Hard) | 525 Min | ≥ 400 |

| HD (Hard) | 620 Min | ≥ 500 |

| HE (Extra Hard) | 695 Min | ≥ 590 |

| HS (Spring Hard) | 720 Min | ≥ 650 |

![Phosphor Bronze Grade-III [ PB-III ]](/wp-content/uploads/2018/08/RCI-Logo-01.png)