| Alloy Names (as per RoHS specifications) | |

|---|---|

| DIN CEN/TS 13388 | CW004A |

| UNS | C11000 |

| Chemical Composition | Weight percentage |

|---|---|

| Copper [Cu] | 99.9 % |

| Oxygen [P] | 50 to 400 PPM |

| Lead [Sn] | 0.005% Max. |

| Total Impurity | < 0.02% |

| Characterists |

|---|

|

| Main Applications |

|---|

| Electrical : Foil wound transformers in electrical panels & transmissions, Electrical bus bars & conductors, Components of electrical switches, anodes, cable wrap acts as shielding tape, able tape in the form of ultra-thin foil of 40 micron thickness in power cables, Terminals, Contacts, Flexible Busbars, XLPE Cable Wrap/Shielding Tapes . Industrial : Heat Sinks, Stamped/Punched parts, Chlorine Battery Caps. |

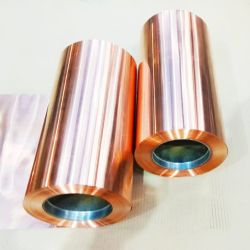

Copper ETP

Properties

| Density | 8.89 | g/cm³ |

| Thermal expansion coefficient - 191 .. 16 | 14.1 | 10-6/K |

| 0 .. 300 °C | 17.7 | 10-6/K |

| Specific Heat Capacity | 0.386 | J/(g.k) |

| Thermal Conductivity | 394 | W/(m.k) |

| Electrical Conductivity (1 MS/m = 1 m/(O mm²) | 58"}">> 58 | MS/m |

| Electrical Conductivity (IACS) | 100"}">> 100 | % |

| Thermal coefficient of electrical resistance (0 - 200 °C) | 3.7 | 10-3/K |

| Modulus of elasticity (1 Gpa = kN/mm²) cold formed | 130 | Gpa |

| 127 | GPa |

| Designation | TENSILE STRENGHT | ELONGATION | HARDNESS | GRAIN | ||||

| Rm (N/mm²) | A50 MM % thickness ≤2,5mm | A50% thickness >2,5mm | HV | MM | ||||

| Min. | Max | Min. | Min. | Min. | Max | Min. | Max | |

| R220 | 220 | 260 | 33 | 42 | - | - | - | - |

| H040 | - | - | - | - | 40 | 65 | - | - |

| R240 | 240 | 300 | 8 | 15 | - | - | - | - |

| H065 | - | - | - | - | 65 | 95 | - | - |

| R290 | 290 | 360 | 4 | 6 | - | - | - | - |

| H090 | - | - | - | - | 90 | 110 | - | - |

| R360 | 360 | - | 2 | - | - | - | - | - |

| H110 | - | - | - | - | 110 | - | - | - |

| Shearing | * * |

| Deep Drawing | * * * * |

| Surface Treatment | * * * * |

| Welding | * * * * |

| Bending | * * * |