| Alloy Names (as per RoHS specifications) | |

|---|---|

| DIN CEN/TS 13388 | CW024A |

| UNS | C12200 |

| JIS | C1220 |

| Chemical Composition | Weight percentage |

|---|---|

| Copper [Cu] | 99.9 % |

| Phosphorus [P] | 0.015% to 0.04% |

| Characterists |

|---|

|

| Main Applications |

|---|

| Architecture : Downspouts, Gutters, Flashing, Roofing, Building Heater Units, Condenser Sheets. Consumer: Air Conditioners, Refrigerators. Electrical : Wire Connectors, Heater Elements ,Solar panels. Industrial : Construction, Rotating Bands, Kettles, Anodes for Electroplating, Heat Exchanger Shells, Oil Coolers, Tanks,Casting Molds, Plating Anodes, Racks, Plating Hangers, pressure vessels, Rivets & nails. |

| Electrical Conductivity | |||

|---|---|---|---|

| The electrical conductivity depends on chemical composition, the lever of cold deformation and the grain size. A high level of deformation as well as a small grain size decrease the conductivity. |

| Corrosion Resistance | |||

|---|---|---|---|

| Cooper is resistant to: natural and industrial atmospheres as well as maritime air, drinking and service water (if the flow rate is not excessive),non oxidizing acids, alkaline solutions and neutral saline solutions. Copper is not resistant to: Ammonia, halogenide, cyanide and hydrogen sulfide solution and atmospheres, oxidizing acids and sea water (especially at high flow rates). |

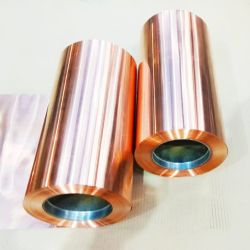

Copper DHP

Properties

- Physical Properties Typical values in annealed temper at 20 °C (Just for Information)

- Mechanical Properties (According EN 1652)

- Fabrication Properties

| Density | 8.9 | g/cm³ |

| Thermal expansion coefficient - 191 - 16 °C | 14.1 | 10‾⁶/K |

| 20 - 300 °C | 176 | 10‾⁶/K |

| Specific Heat Capacity | 0.386 | J/(g k) |

| Thermal Conductivity | 330 | W/(m k) |

| Electrical Conductivity (1 MS/m = 1 m/(Ω mm²) | ≥ 47 | MS/m |

| Electrical Conductivity | 81 | IACS % |

| Thermal coefficient of electrical resistance (0 - 300 °C) | 3.4 | 10‾³/K |

| Modulus of elasticity (1 Gpa = kN/mm²) | 132 | Gpa |

| Temper | Tensile Strength Rm | Yield Strength Rp0.2 Minimum | Elongation A50mm Minimum | Hardness HV** |

| Mpa | Mpa | % | HV | |

| R220 | 220 .. 260 | < 140* | 33 | 40 .. 65 |

| R240 | 240 .. 300 | 180 | 8 | 65 .. 95 |

| R290 | 290 .. 360 | 250 | 4 | 90 .. 110 |

| R360 | ≥ 360 | 320 | 2 | ≥ 110 |

| * only information. ** only for reference. |

| Cold Formability | Excellent |

| Hot Formability | Excellent |

| Soldering | Excellent |

| Brazing | Excellent |

| Oxyacetylene Welding | Good |

| Gas Shielded Arc Welding | Excellent |

| Resistance Welding | Not Recommended |

| Machinability | Not Recommended |